Introduction:

Procurement Resource is excited to unveil its latest report, "Polyethylene Terephthalate (PET) Production Process with Cost Analysis." This comprehensive analysis offers deep insights into the PET production process, procurement strategies, and cost structures, enabling business leaders to maintain a competitive edge in the ever-evolving global plastics industry.

Request Free Sample - https://www.procurementresource.com/production-cost-report-store/polyethylene-terephthalate-pet/request-sample

Procurement Resource Assessment - Polyethylene Terephthalate (PET) Production Process:

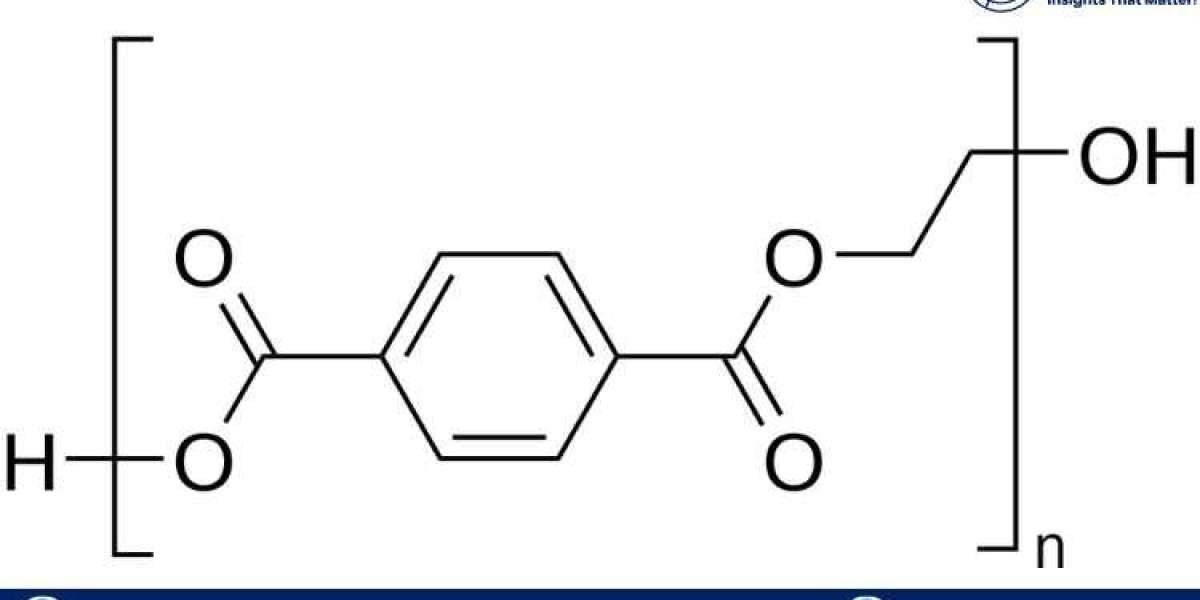

The report thoroughly examines the polyethylene terephthalate (PET) production process, focusing on the primary methods used to manufacture this widely adopted polymer:

Direct Esterification Process: In this process, purified terephthalic acid (PTA) is directly esterified with ethylene glycol (EG) under heat to produce bis-hydroxyethyl terephthalate (BHET). The BHET undergoes polycondensation in the presence of catalysts to yield PET.

Transesterification Process: Here, dimethyl terephthalate (DMT) is reacted with ethylene glycol, forming bis-hydroxyethyl terephthalate. The subsequent polycondensation produces PET with varying molecular weights, suitable for diverse applications.

The report provides detailed analysis for both methods, covering aspects like esterification, catalyst selection, polymerization conditions, and best practices to ensure optimal yield and quality.

Product Chloride:

Chloride content is often minimized or controlled in PET production because chlorine can act as a catalyst poison, affecting the reaction and compromising product quality. Traces of chlorides may occur due to residual impurities in raw materials, especially in catalysts. The report provides guidelines on managing chloride contamination to ensure PET remains of high purity.

Market Drivers:

The report identifies key market drivers influencing global demand for PET:

Packaging Industry: PET's lightweight, shatter-resistant, and recyclable properties make it a primary choice for packaging applications, especially for bottled beverages, containers, and packaging films.

Textiles and Fibers: Polyester fibers, derived from PET, are widely used in apparel, home textiles, and industrial fabrics, driving demand for this versatile polymer.

Automotive Industry: PET finds applications in automotive interiors due to its durability, strength, and lightweight properties.

Electronics and Consumer Goods: The increasing use of PET in electronics and consumer products continues to boost demand.

Raw Materials Requirements:

The report provides a comprehensive overview of the raw materials essential for the Polyethylene Terephthalate PET production process. Key materials include:

Purified Terephthalic Acid (PTA): The primary precursor in direct esterification. Sourcing high-purity PTA ensures the final PET quality.

Dimethyl Terephthalate (DMT): Used in transesterification to produce PET.

Ethylene Glycol (EG): An essential component that reacts with PTA or DMT to form PET.

Catalysts and Additives: Catalysts like antimony or titanium are used in polymerization. Additives like UV stabilizers enhance PET properties.

Costs and Key Process Information:

Procurement Resource's report provides a comprehensive cost analysis of the PET production process, including:

Raw Material Costs: Expenses related to sourcing purified terephthalic acid, dimethyl terephthalate, ethylene glycol, and catalysts.

Utility Costs: Energy, water, and waste management expenses across various production stages.

Labor Costs: An analysis of labor requirements and associated costs across regions.

Overhead Costs: Indirect expenses like regulatory compliance, logistics, maintenance, and storage.

The report also provides key process information, such as yield rates, cycle times, and efficiency metrics. This data empowers manufacturers to identify optimization opportunities and streamline production.

Looking for an Exhaustive and Personalized Report?

Procurement Resource's "Polyethylene Terephthalate (PET) Production Process with Cost Analysis" report is designed to deliver actionable insights that substantiate your business strategy. Whether you're launching a new production facility or optimizing an existing one, this report offers:

Comprehensive Data: Detailed information on production processes, cost structures, and market trends.

Customizable Insights: Tailored to your specific business needs, ensuring you receive accurate data for strategic decision-making.

Competitive Intelligence: Insights into market dynamics, key competitors, and emerging opportunities.

Procurement Resource's expertise and in-depth analysis will provide your business with a vital advantage in the competitive global PET market. Contact us today for a personalized consultation or learn how this report can be customized to meet your unique requirements!

About Us: